III Unser STARlight

DURAVOLTA is a newly developed heat stabilized flame retardant Polypropylene material, made in Germany.

DURAVOLTA is the ideal alternative for Formex GK, Formex GK-17, Formex GK-10, Formex GK-30, Formex GK-40

It provides unique features that meet many industry flammability standards including the component program of Underwriters Laboratories, Inc. classification of UL 94 V-0 and UL 94 VTM-0.

THINK GREEN – Protect the world

USE THE ADVANTAGE

USE DURAVOLTA

DURAVOLTA is a halogenfree material according to IEC 61249-2-21 with outstanding heat and electrical insulation properties

DURAVOLTA combines high technical properties , easy converting possibilities , high dimensional stability and

ecological aspects at a cost effective prices!

Advantages of DURAVOLTA

- halogenfree according to IEC 61249-2-21

- outstanding RTI el of 120°C according UL 746B

- very good electrical insulation properties by high resistivity‘s and dielectric strength

- non hygroscopic

- very high chemical resistance

- very good processing properties

- RoHS and WEEE compliant

- producable in thicknesses according your needs

- recyclable

- made in germany

III Application

Because of its fire rating, easy converting to 3D parts and its outstanding electrical insulation properties up to a continuous temperature of 120°C, Duravolta has won acceptance in variety applications like:

- computers and computer peripherals

- electrical and power distribution system

- telecommunications equipment

- conventional and uninterruptible power supplies

- fire barriers

- Blanking (filler) panels for better air flow control in data center or containment system

- Lighting (especially LED)

- automotive components

- automotive Komponenten

- charger and battery stations

- consumer products, TVs & appliance

- medical equipment

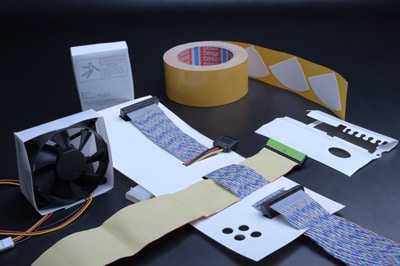

Electrical insulation

Electrical insulation  Wire harness organizer

Wire harness organizer Self adhesive parts

Self adhesive parts Electrical insulation

Electrical insulation Air flow baffles

Air flow baffles EMI / RFI shielding

EMI / RFI shielding Fire barrier

Fire barrier Electrical insulation

Electrical insulation

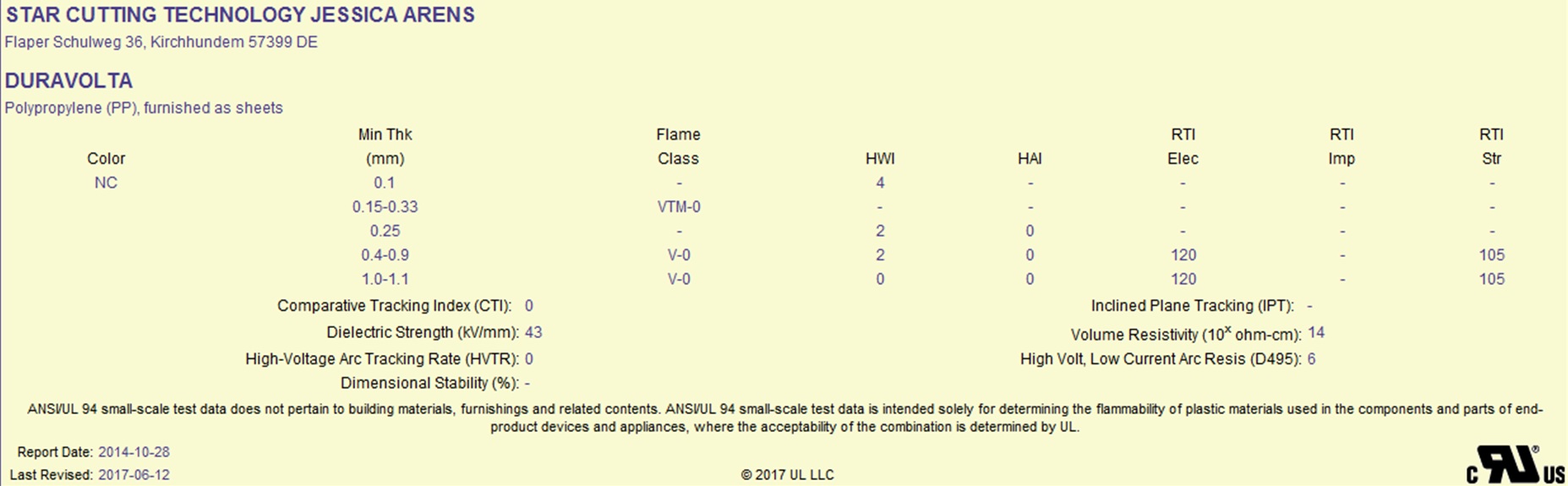

III Technical datas

Duravolta is flame retardant Polypropylene with unique properties and recognized under the component program of Underwriters Laboratories, Inc.

Detailed Technical Datas :

| tensile strength | ISO 527-2 | N/mm² | ≥ 18 |

| elongation at break | ISO 527-2 | % | ≥ 50 |

| Impact strength | ISO 179, 23°C | kJ/m² | ≥ 55 |

| Notched impact strength | ISO 179, 23°C | kJ/m² | ≥ 1,5 |

| Flexural modus | ISO 178 | N/mm² | ≥ 2200 |

Outstanding properties

- halogenfree according to IEC 61249-2-21

- flame retardant according UL94 V0/VTM0

- RTI el = 120°C

- CTI = 0

- Dielectric strength = 43 kV/mm

III Our delivery range

-

Duravolta 10

0,10 mm

Rolls, 610 mm width

-

Duravolta 43

0,43 mm

Rolls 610 & 1000 mm width

-

Duravolta 12

0,125 mm

Rolls, 610 mm width

-

Duravolta 72

0,72 mm

Sheets 2 x 1 m

-

Duravolta 25

0,25 mm

Rolls, 610 mm width

-

Duravolta 100

1,00 mm

Sheets 2 x 1 m

- other thickness up to 100 mm or different width and length on request

- as granulate

- as finished part (cut & bend, milled, thermoformed etc.)

III processing methods

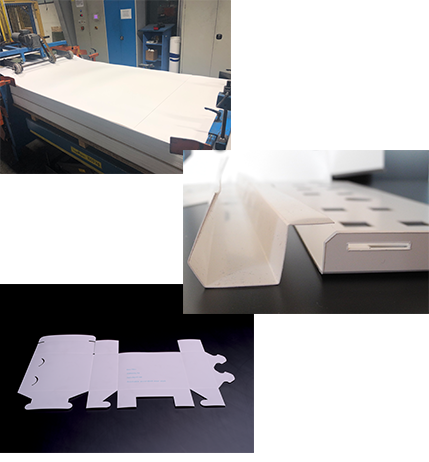

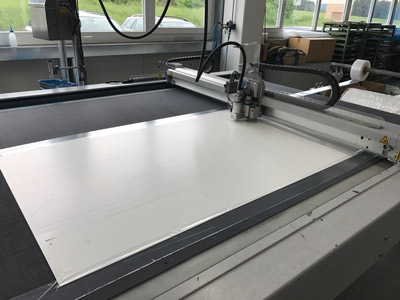

DURAVOLTA is mainly delivered in sheets and rolls and easily convertable into 2D or 3D parts. The following processing methods are possible:

Cutting:

- cutting press with a steel rule tool

- cnc knife table

- cnc laser or water jet machíne

- cnc milling machine

Bending:

- Manual

- Manual or hydraulic press break machine

Others:

- Printing and signing

- Embossing with logos or creasing lines

- Lamination with different materials

- Lamination with adhesive

- Low cost heat forming

- Thermoforming by a machine

- Injection moulding

- Welding (heat, ultrasonic)

Assembly Methods:

There are many possibilities to assemble the parts together for a 3D part

Cutting with

knife table

Cutting with

Cutting press

Bending by hand

Cutting with

Laser or water jet

Cutting with

milling machine

Printing / signing

Want more information about DURAVOLTA?

Please send us your questions in the form and we will get back to you.