Bending film

STAR Premium Bending film

Impression-free production of your bending parts with STAR bending foil

Star quality edging foil for placing on the edging tools (also called bottom tools, die of the edging die) for impression-free edging of sheets on press

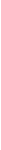

Bending foil from the market leader in various thicknesses and widths

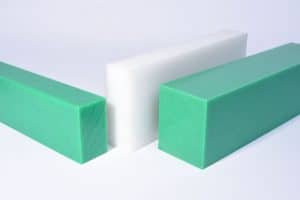

A big problem in sheet metal working is the bending marks on the bending parts caused by the contact of the workpieces with the bending tools during bending. The sheet metal is scratched and gets abrasions due to the press force of the press brake when bending radii / an angle at the contact points with the lower tool. The function of the press brake foil is very simple and straightforward. It is placed on a width of 100mm, 150mm or 200mm (other dimensions also available) during bending on the machine (also on CNC machines) on the side to be protected between workpieces (either on the dies or under the sword) and sheets. The machine then presses on the side to be protected on the edging foil and the edging foil protects the metal (even powder-coated) from line formation. For fixing on the press brake e.g. magnets can be used.

The strengths of STAR edging foil

STAR PremiumAF edging foils are quality foils made of high-strength PU and have been developed and tested by leading manufacturers of edging presses (as a winner in comparison with cheap PVC foils as well as in comparison with special fabrics). The quality of STAR press brake foils lies in their high tensile strength and long service life due to frequent bending on the same spot. The bending tools are protected (longer service life), you avoid expensive reworking (especially in the case of subcontracting) and rejects, and the use of the bending foil on the presses is profitable from the very first use.

Do you want more information about edging foil?

Please send us your questions in the form and we will get back to you.