Shooting range processing

Shooting range lining - processing tips

Processing tips from our customers

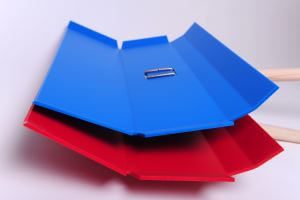

The processing of the plastic sheet material can be done with the help of woodworking machines. Circular saws, drilling machines and routers are best suited. Tip: The material should not be processed with too much pressure and highest speeds in order to avoid too much frictional heat, which can theoretically melt the material at the edges.

Processing tips - learning from the experience of others

The material can be fixed to a wooden structure. It should be borne in mind that the material has a higher coefficient of expansion and so will want to contract at low temperatures and expand at higher temperatures. On a length of 1,000 mm and a temperature difference of +20°C, a panel will extend by 4 mm. Therefore we would give the following installation tips

- provide for expansion possibilities of the material by overlaps

- store the material before installation at the average room temperature for about 24 h before installation or processing

- if there are big heat differences in your shooting range, we would recommend to install the panels at the average temperature to compensate the deflections up and down.

- if possible, work with oblong holes in case of big temperature differences

Tip : To get a uniform image and a really matte surface, you can sand the surface with a very fine lubricating gel paper.

These tips are to help you with the installation, but you are welcome to talk to a reference customer and talk about the trouble-free installation.