PE 300 (Polyethylene/PE HD)

Semi-finished products such as sheets, welding rods, round rods and machined finished parts made of polyethylene 300 (PE HD)

PE HD : The material - technical properties

The material PE High-Density (high density polyethylene, short form: PE-HD,PE 100 in a family with PE HMW and PE-UHMW) is the technical PE , which is very good weldable !***

Light - but good

Like all polyethylene grades (PE-HMW, PE-UHMW allsamt polyethylene with high molecular weight and thus high technical properties), polyethylene 300 is an engineering plastic (thermoplastic) that is very easy to process. Like all PE types, PE 300 has the second-lowest weight of all high-quality engineering plastics (lower only PP – density at 0.92) at approx. 0.95 g/cm³ (for comparison PVC = 1.4 / PA = 1.14 / POM = 1.39 / PTFE = 2.2 / PEEK = 1.32 / PVDF = 1.78) and thus alone offers a very interesting price basis (compared to PA, POM, PEEK, PTFE, PVC, PVDF).

Water and chemicals - no problem for PE-HD

The moisture absorption of PE-HD is 0.0% (better than PA), the modulus of elasticity is a low 800 N/mm², but due to its high chemical resistance (better than POM, PA, PVC) and simple plastic processing (cutting, milling, turning, water jet cutting, welding (no evaporation as with PVC / PVC-U.) PE-HD is a very popular material for technical plastics that require good properties such as chemical resistance and elongation at break.

In contrast to PE-UHMW and PE-HMW can be welded without problems) a very popular material for technical plastic parts with low weight in mechanical engineering, which are required to have good properties such as chemical resistance and elongation at break, and PE 300 is mostly used as a container construction material or in ventilation technology.

The sliding properties of PE HD sheets are lower than those of ultra-high molecular weight PE or PE HMW.

PE-HD - direct comparison with other engineering plastics

Plastic sheets made of PE HD have the above-mentioned good properties and are superior to many other engineering plastics.

Compared to sheets made of PVC, which also withstand many chemical substances due to their high chemical resistance, PE-HD sheets have approx. 45% less weight and no toxic gases are produced either during machining or when polyethylene sheets or round rods are burned.

Compared to plates made of PA, POM and PEEK plastics, the sliding properties of polyethylene plates are higher. In comparison with PP, PE HD is also much more resistant to cold (PPH has its glass transition temperature, which is the temperature at which sheets can break under simple load, at about 0°C, PP CoPo at about -40°C, PE-UHMW at -280°C).

Contact with food is the same for PE-HD as for PE-HMW and PE-UHMW is physiologically safe and unproblematic due to FDA and ISO approval. The moisture absorption of PE-HD is close to zero, which is a problem for PA in many applications.

In terms of price, PE-HD is usually far more attractive than ultra-high molecular weight PE (PE-UHMW), PA, POM, PEEK, PVC or PTFE and slightly better than PE-HMW. Note : The only weak point of PE HD is its static strength.

Usually you have to support the material polyethylene by design and cannot e.g. design plates / components with wide support distance from it and have to avoid high surface pressures.

In contrast to POM, PA, PE-HMW or PE-UHMW, PE-HD can be welded very well with welding rod (in ventilation technology, for example, exhaust air ducts are then built from it). In addition to welding with welding wire, the material can also be mirror welded (as can PE-UHMW or PE-HMW).

PE-HD / PE 300 - the manufacturing process

PE-HD is usually extruded as sheets in thicknesses of 1-20 mm (up to 50 mm theoretically possible) (like PC / acrylic glass). However, PE HD can also be pressed like the other polyethylene types (sheets up to 200 mm thick).

Round rods and welding rods can be produced like PVC, POM, PA, PVDF or PP. Welding rods are available in various cross-sections such as round or triangular.

Thickness tolerance - little is possible

The extruded sheets then have a tolerance of about +/- 0.2 , pressed sheets usually +/- 2 mm and are planed to +/- 0.2 mm tolerance.

PE-HD sheet material usually used as container wall or bottom or milled into finished parts, the round bars are turned into drawing parts (good machinability with woodworking machines is given).

Regenerated sheets made of PE-HD - recycling no problem

Own leftovers from the material polyethylene like planing waste or off-cuts can be ground again and extruded or pressed to high-quality PE reclaimed sheets.

Depending on the quality, these plastic sheets made of reclaimed material cannot be distinguished externally from new ultra-high molecular weight PE sheets. In some cases, however, the sheets have optical limitations such as pimples or small holes on the surface, which are then used more for root protection or minor tasks.

We are happy to advise you here.

Dimensions and thickness / thickness PE-HD sheets - engineering plastics

We offer plastic sheets pressed and extruded from PE-HD with thicknesses (thickness) up to 280 mm void-free and stress-free, justified by the above-mentioned production processes, as well as blanks and molded parts / technical plastic parts (milled parts, turned parts) from PE sheets or round bars.

Mostly the pressed sheets are pressed or extruded in large sheets , e.g. 4 x 2 m and divided to smaller standards or cut to size according to your requirements.

The boards are usually planed and have a very good tolerance in thickness. The round bars are supplied with a tolerance in the plus range.

Colors - almost everything possible, but only a few colors standard.

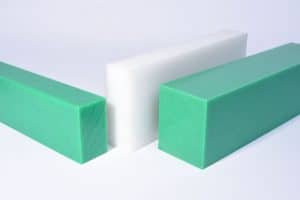

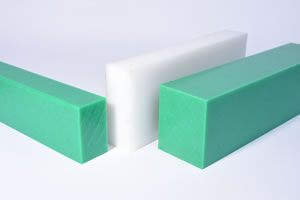

Standard colors are natural (whitish) and black, the regrind is colorful or black, translucent / transparent as with PC (e.g. Makrolon) or acrylic glass is not possible with PE HD.

The PE-300 price - with little waste an attractive price attracts

The degree of utilization decides the final price of the required cuttings, we can grind up leftovers and press them into PE HD regenerated sheets (mostly black or colored, natural is not possible with regenerated without defects).

Inquiries PE -HD - technical plastic

Delivery quantities of this PE HD are as pressed sheets also single pieces, extruded sheets are in many formats and thicknesses in natural and black in stock, round bars are extruded in many formats and colors in stock.

For quotations on PE-HD sheets or molded parts such as impact protection strips, just ask us, we will be happy to make you an offer.

Do you want more information about PE 300 (Polyethylen/PE HD)?

Please send us your questions in the form and we will get back to you.

Colors

- Natural

- Black

Sizes extruded sheets ( material thickness 1 – 30 mm )

|

2000 x 1000 mm

|

3000 x 1500 mm |

We will gladly cut your desired format from one of our standard formats!

( Not all intermediate sizes occupied! Special dimensions / thicknesses are possible from minimum quantities of 5 t )

If you have any questions, please contact us by phone or e-mail.

Colors

- Natural

- Black

Formats pressed plates ( material thickness 8 – 140 mm )

| 2000 x 1000 mm |

3000 x 2000 mm

|

4000 x 2000 mm

|

We will gladly cut your desired format from one of our standard formats!

(No standard! Minimum quantities of approx. 5 t required. )

If you have any questions, please contact us by phone or e-mail.